PCB V-scoring, often referred to as V-groove scoring or simply V-scoring, is a precise technique used in the PCB manufacturing process to streamline the separation of individual PCBs from a larger panel. This method, highly valued in the electronics industry, ensures efficient production and easy depanelization while maintaining the integrity of the boards.

What is PCB V-Scoring?

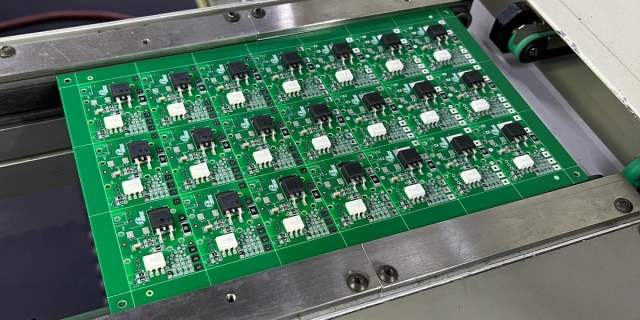

PCB V-Scoring is a manufacturing method where V-shaped grooves are scored into the surface of a PCB panel. These grooves are designed to make the separation of individual PCBs easier after assembly and soldering. The process ensures the boards remain connected by thin tabs of uncut material, which can be effortlessly snapped apart along the grooves.

Here's how the process works:

-

Panelization: Multiple PCBs are fabricated on a single panel to improve efficiency and reduce waste.

-

V-Groove Routing: V-shaped grooves are routed into the panel, leaving a small amount of material to hold the boards together. Typically, one-third of the board thickness remains intact.

-

Assembly: Components are placed and soldered onto the panel, ensuring all boards are assembled in a unified process.

-

Separation: After assembly, individual PCBs are separated by snapping along the V-groove lines, either manually or using automated tools.

Advantages of PCB V-Scoring

-

Efficiency in Production

PCB V-Scoring optimizes the production process by enabling multiple boards to be manufactured on a single panel. This reduces handling time and material waste, significantly lowering production costs. -

Space Optimization

The panelization approach allows boards to be placed closely together, minimizing unused space. This is particularly beneficial for projects requiring high volumes of PCBs. -

Precision and Clean Edges

The scoring method ensures clean and precise separations, leaving the board edges intact. This makes it an ideal solution for industries where aesthetic and functional quality is paramount. -

Reduced Stress During Separation

Compared to methods like tab routing or mouse bites, PCB V-Scoring minimizes mechanical stress on the boards, making it suitable for sensitive designs. -

Enhanced Scalability

This technique is perfect for projects that demand high scalability, such as in consumer electronics or industrial automation.

Considerations for PCB V-Scoring

While PCB V-Scoring offers numerous advantages, it may not suit all designs. Boards with sensitive components near the edges could experience slight mechanical stress during separation. Additionally, not all manufacturers include V-scoring as a standard option, so discussing project requirements with your manufacturer is crucial.

The Role of PCB V-Scoring in PCB Assembly

The PCB assembly process benefits significantly from V-scoring. Panelized PCBs allow for easier handling during component placement and soldering. After assembly, the V-grooves facilitate swift separation without requiring additional equipment or techniques. This ensures a smoother workflow and saves time in the manufacturing process.

How Anzer Supports PCB V-Scoring

At Anzer, we prioritize precision and efficiency in every aspect of PCB manufacturing. Our expertise in PCB V-Scoring ensures that your projects benefit from clean separations, reduced stress, and optimal space utilization.

We offer an array of high-quality products that integrate seamlessly into your PCB assembly process, including:

-

Discrete I/O Modules for reliable and efficient control systems.

-

Discrete I/O Mounting Boards designed to support complex assembly needs.

-

W1492 Wiring & Signal Conditioning Products that enhance functionality in demanding applications.

With our commitment to quality and innovation, we provide tailored solutions that elevate your manufacturing projects. Whether you're producing high-volume PCBs or intricate prototypes, Anzer is your trusted partner for excellence in electronics manufacturing.

Conclusion

PCB V-Scoring is a vital technique that enhances efficiency, precision, and scalability in the PCB manufacturing process. From enabling cost-effective production to reducing stress during separation, its advantages make it a preferred choice for industries requiring high-quality PCBs.

When you choose Anzer, you're not just opting for superior products but also partnering with a team that's dedicated to your success.